In October 2018, the U.S. Army Corps of Engineers – Louisville District opened the long-awaited Olmsted Locks and Dam on the Ohio River, a major river artery of the east-central United States.The Olmsted Locks and Dam will relieve a choke point created at Locks 52 and 53, which hampered the flow of export grain, causing cost efficiencies for shippers and barge operators. The elimination of this cost and uncertainty will make the U.S. more competitive in the world market and ultimately improve soybean prices for producers upriver.

Olmsted Locks and Dam’s new design is very important during periods of high water, generally January through May. Tainter gates and wickets take advantage of the periods of plentiful water supply to navigate over the wickets and not have to stop to be locked through. When working properly, wickets are a tremendous benefit. Due to the age of Lock 52 and 53, raising and lowering the wickets was an area of concern. Olmsted’s new dam design with a lowered door helps the wickets and tainter gates open and close, relieving this concern. Unlike the old wickets, these wickets are made from steel versus wood. Steel is believed to be more durable and interchangeable than the old design.

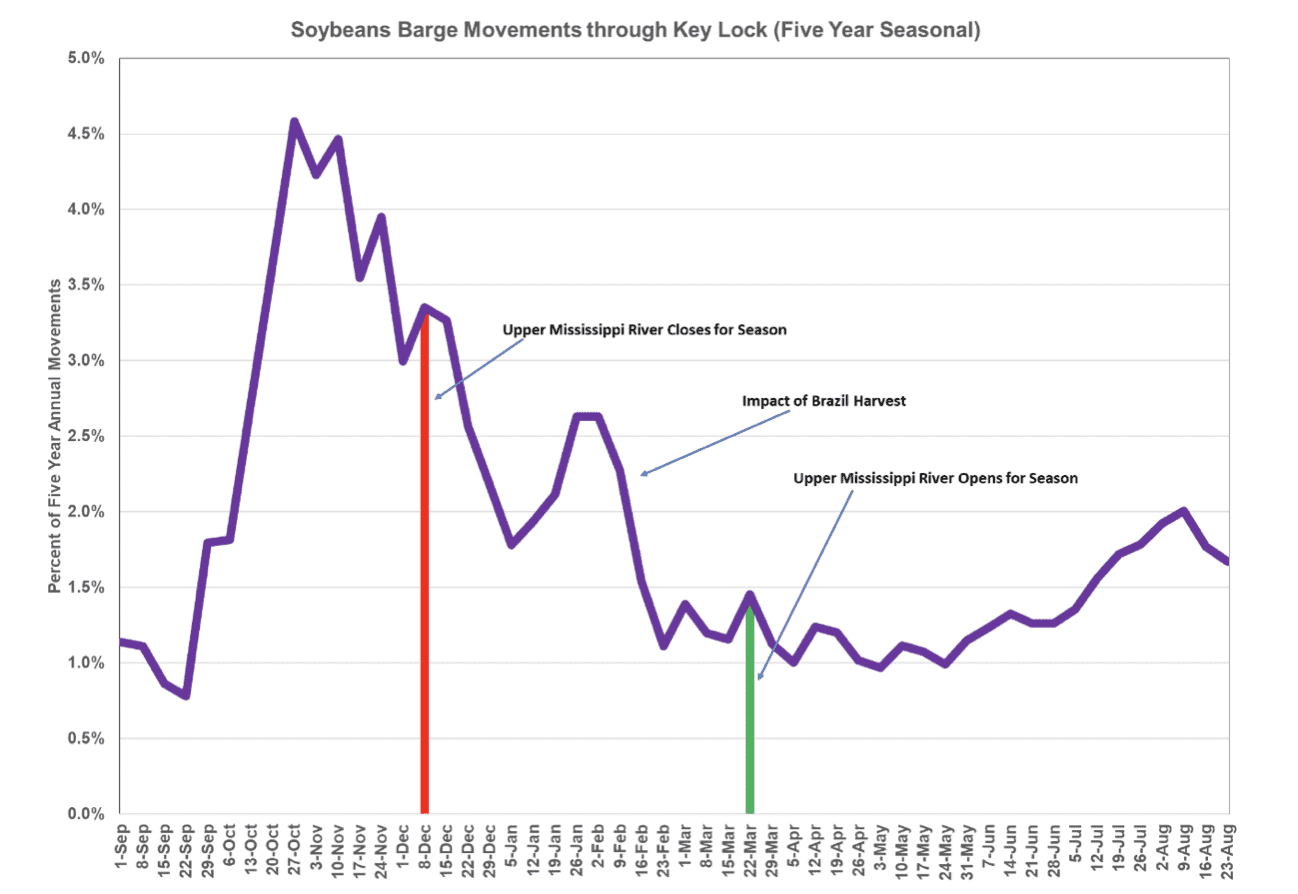

Seasonal soybean barge movements point to the importance of an efficiently working inland Mississippi River system. Although opening Olmstead is a very large step, more help is required for other locks on the upper reaches of the inland Mississippi River system. Waterways are not a part of the average American’s everyday life, which makes it is important for organizations such as the U.S. Soybean Export Council (USSEC) to continue to educate the public and policy makers on the importance of the waterways to the health of America’s farmers.