09.25.2024

U.S. Soy Staff Writer

This “biocomposite” producer delivers biodegradable, soy-based composite boards for the furniture, cabinetry and building industries. Recently, the venture-capital newsletter fundedIDEAS recognized e2e Materials as one of its “Top 300 Startups” for demonstrating an ability to adapt to changing market demands.

“It feels nice to know that someone recognizes the work that we do,” said Clayton Poppe, director of engineering for e2e Materials. “The company earned recognition for producing an American manufactured product that is 100 percent biodegradable.”

Lighter, Safer Option with Soy

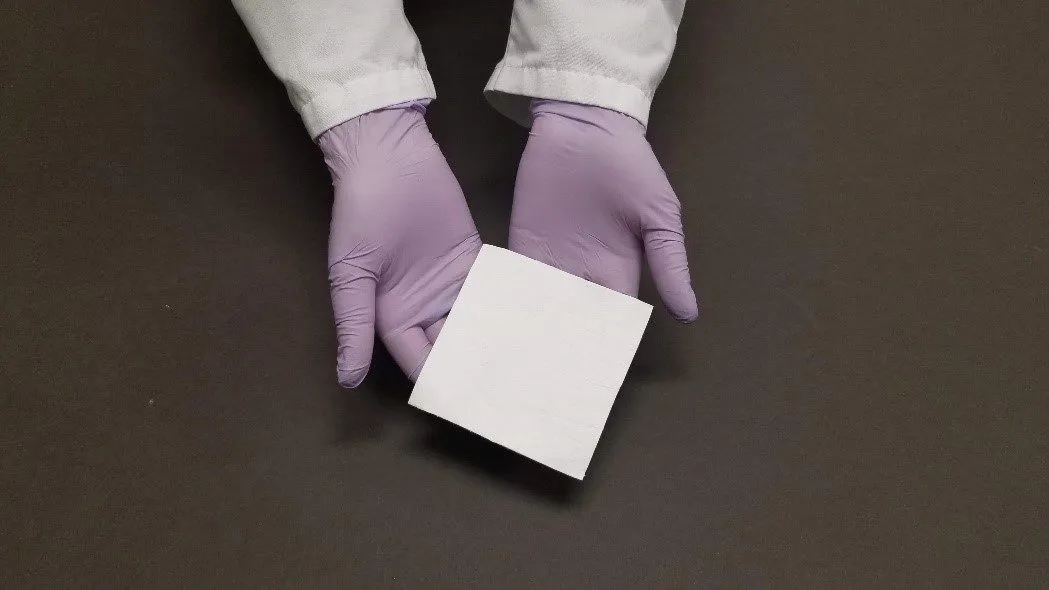

e2e Materials produces high-strength, lightweight composites with soy-based resin and grasses like jute, flax and kenaf. According to e2e, the soy-based biocomposites deliver a lighter, safer and cheaper option than formaldehyde-laden wood composites.

The United Soybean Board (USB) helped pave the way for e2e’s product by funding research, initially developed at Cornell University, to help bring the product to the market.

“Working with the USB helped develop the molding process and launch our new products,” added Poppe. “Without the technical support we received from USB for product development, our newest product would not have been possible.”

Reducing the Carbon Footprint from Autos to Skateboards

Aside from producing a stronger product, e2e also cuts its carbon footprint during the manufacturing process. Their biocomposites require two-thirds less energy and less raw material than a competitive particle board.

The composites go into everything from building materials to skateboards, including office furniture products, automotive components and kitchen cabinets. On skateboards, the composites replace fiberglass or carbon fiber in the skateboard decks. On other products the composites replace wood or wood composites and plastics.

Soy innovations are constantly changing. The content here captures a particular innovation at a point in time as noted by the original publish date found at the top of the case study. Since it was published, the information, company, science and more may have been updated.

U.S. Soy Staff Writer

U.S. Soy provides a sustainable alternate protein, that allows our farmers to grow their businesses and feeds countless families around the world.