04.17.2024

Laura Temple

The United Soybean Board teamed up with The Yield Lab Institute and AWS Startups to create the Soy Innovation Challenge, where entrepreneurs use new technology and U.S. Soy to solve sustainability challenges. The Soy Innovation Challenge provides mentorship, networking, training and soy checkoff funding to advance their U.S. Soy solutions. Check out the innovations from the four finalists in this article series.

Are you sitting down for this?

If your seat is cushioned, you likely are sitting on petroleum-based synthetic polyurethane foam, or polyfoam. It’s the industry standard soft fill for furniture, mattresses, seats in cars and planes and much more.

For the team of entrepreneurs that created EDEN Concept Fill, the fact that comfortable seating and mattresses rely on oil-based synthetic polyfoam is a problem worth solving.

“We all worked in the furniture manufacturing industry,” says CEO Jeff Lazar. “Upholstered furniture was our world.”

Lazar and his team set out to develop fully biobased furniture in a way that could make a global impact. As they went down the materials list, they quickly realized eliminating petroleum from cushioning would be a key challenge.

They clearly understood both the performance benefits of polyfoam cushioning and its limitations and drawbacks.

“We bought millions of dollars’ worth of synthetic polyfoam,” he explains. “We know that it lasts 1,000 years in landfills.1 Its costs fluctuate with crude oil prices. And, no other options are available.”

As they tackled this challenge, they connected with the National Renewable Energy Laboratory, or NREL.

“They became our research and development group, and they helped us to find a solution that eliminates petroleum — cellulose,” Lazar says.

Cellulose makes up the walls of plant cells and plant fibers. And now, with this technology, it can also make biobased cushion fill with performance equal to or better than synthetic polyfoam, a new product called CellyFill.

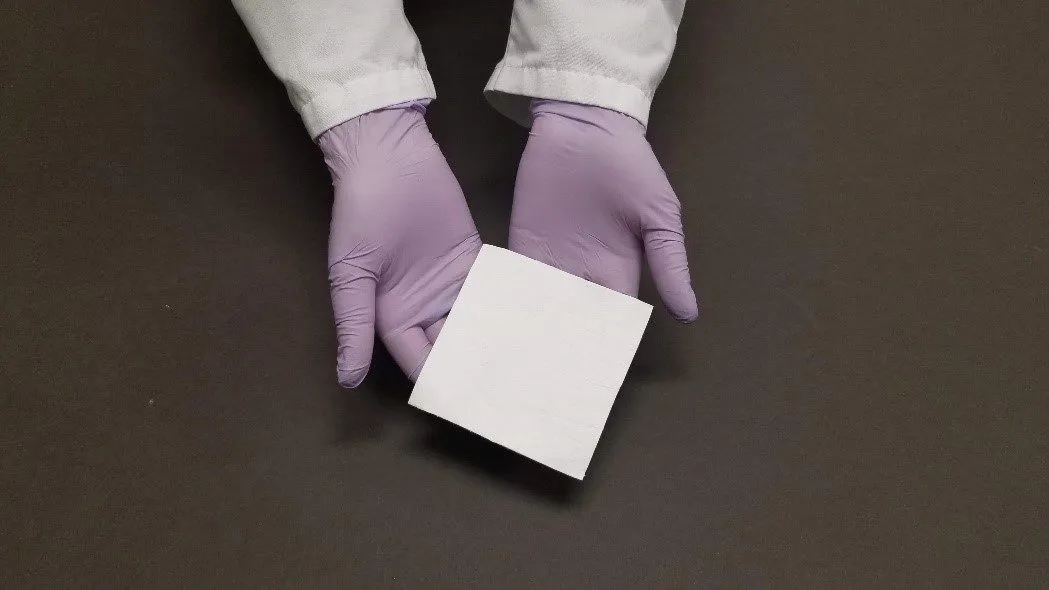

A CellyFill cushion, which can be made from soybean hulls and biobased materials. CellyFill products provide performance equal to or better than petroleum-based polyfoam.

Sourcing Cellulose

While CellyFill can be made from many biobased raw materials, Lazar and NREL worked to identify the best options. They sought sources with a high concentration of cellulose. At the same time, NREL connected the Eden Concept Fill team with The Yield Lab Institute, leading them to a promising option: soybean hulls.

“We know furniture, not agriculture,” Lazar says. “Through this connection, we learned that soybeans carry the greatest concentration of cellulose in their hulls.”

Soybean hulls are usually removed from the beans when they are crushed and the oil is separated from the protein-filled meal. While a small percentage get incorporated into animal feed, they are often considered a waste product.

“With this option, there is no need to add more cropping or water use to produce,” he explains. “And, soy is available worldwide. Our technology is scalable and we want to make it available everywhere, so raw material needs to be readily available. Soy hulls would be.”

A More Sustainable U.S. Soy Solution

Lazar notes that the industry is familiar with the sustainability of soy as a renewable resource. Previous efforts to improve the sustainability of cushioning resulted in a synthetic polyfoam option that is about 20% soybean oil and 80% petroleum.

“What makes CellyFill even more sustainable is that we are eliminating petroleum completely,” he says. “Our cushioning can be fully bio-based, with soy hulls as the primary feedstock.”

Soybean oil also serves as a primary feedstock for some renewable fuels, so demand for that portion of soybeans is growing. The capacity to crush soybeans for their oil and meal is increasing significantly in regions, including the U.S., focused using more renewable fuel in place of petroleum. Soy hulls are a thin shell on the outside of the beans, which is a different part than where the oil comes from. Their availability will grow along with soybean oil availability.

According to Lazar, the investment the team receives as a Soy Innovation Challenge finalist will go toward further research, development and intellectual property work.

“We know how to minimize moisture content and odor, which are common industry concerns about biobased fill,” he says. “Our next focus will be how to scale up production quickly.”

He credits the Soy Innovation Challenge with helping the EDEN Concept Fill team connect with sources for raw materials.

“We’ve received lots of enthusiasm for soy hulls as a cellulose source,” Lazar says. “Throughout the Soy Innovation Challenge, we’ve been impressed with how proactive the team has been in steering us toward interested contacts to find business synergies and related goals.”

An early version of a sustainable chair using biobased materials. Cushioning is easily made by incorporating soybean hulls as the primary raw material feedstock.

Significant Impact

Lazar believes CellyFill will offer manufacturers and consumers a lower-cost, more environmentally thoughtful option for soft seating and mattresses, without sacrificing performance.

But does the cushioning in your recliner, sofa, mattress or the driver’s seat of your car really make a difference?

“Estimates show that using CellyFill in place of synthetic polyfoam could eliminate 1.1 gigatons of carbon dioxide emissions by 2050,”2 Lazar says. “That represents 42% of UN and worldwide targets.”

That impact is worth sitting down for.

Check out the other finalists in the 2023 Soy Innovation Challenge:

- ISEN, January 22, 2021; Slacker, April 14, 2023.

- CO2 Impact of Polyfoam by Volume, Global, 2021.

Laura Temple

Contributing Editor USSOY.org

Ag communicator Laura Temple tells complex stories from the agriculture industry.