Well-functioning waterways are crucial to U.S. infrastructure and the timely, reliable delivery of U.S. soybeans. For the Olmsted Lock and Dam project, the next steps are the removal of Lock and Dam 52 and 53 that were made redundant by Olmsted Lock and Dam. The demolition of Lock and Dam 53 started after the Olmsted Dam became operational, but the unprecedented high-water event has pushed the removal of Lock and Dam 52 and 53 into 2021. Once the Olmsted Lock and Dam project is totally complete, a tremendous amount of money will be freed up to work on other important major maintenance projects on the Inland Mississippi River System.

According to the U.S. Army Corps of Engineers, the tonnage that transits through or over the Olmsted Dam is approximately the equivalent of 3.6 million semi-tractor trailer trucks annually or 9,800 trucks daily. Without a working Ohio River, all those large 80,000-pound semi-tractor trailers would be adding to the general congestion on local roads.

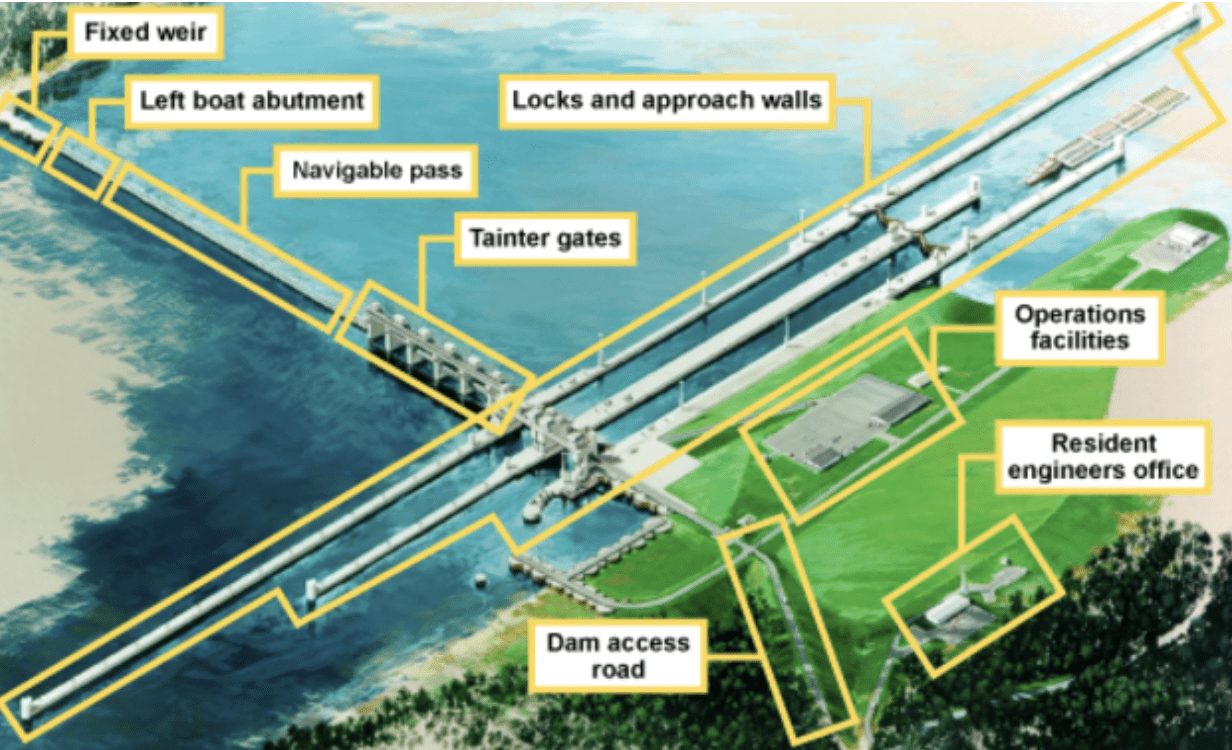

In October 2018, the U.S. Army Corp of Engineers Louisville District opened the Olmsted Locks and Dam on the Ohio River. This project is very important in terms of improving transportation on the Ohio River. The Olmsted Locks and Dam relieve a choke point created at Locks 52 and 53, which hampered the flow of export grain and soybeans that caused cost inefficiencies for shippers and barge operators. Olmsted’s twin 1,200-foot locks eliminate the need to break up and reassemble tows, preventing hours of delays. The elimination of this cost and uncertainty will make the U.S. more competitive in the world market and ultimately improve the soybean price for producers upriver.